-

By:

- ida

- No comment

difference between sop and work instructions

SOPs provide broad guidelines for processes, while Work Instructions offer detailed, task-specific steps. Together, they ensure efficiency and consistency in operational processes.

Definition of SOPs

Standard Operating Procedures (SOPs) are formal, documented processes that outline the steps, actions, and tasks required to complete a specific activity. They provide a broad framework for ensuring consistency, compliance, and efficiency in operational processes. SOPs are designed to be clear, concise, and easily understandable, serving as a reference guide for employees to follow established protocols. By detailing the “what” and “why” behind a process, SOPs help organizations maintain quality, safety, and regulatory adherence. They are often applied across multiple tasks or departments, making them a foundational tool for operational excellence and standardization.

Definition of Work Instructions

Work Instructions are detailed, step-by-step guides that outline the specific actions required to perform a single task or activity. Unlike SOPs, which provide a broader overview, Work Instructions focus on the “how” of a process, offering precise, actionable steps. They are typically used for repetitive, complex, or critical tasks where adherence to exact procedures is essential. Work Instructions often accompany SOPs, breaking down high-level processes into manageable, task-specific directions. They ensure that employees can execute tasks accurately and consistently, minimizing errors and variability. By focusing on the practical execution of tasks, Work Instructions play a crucial role in operational efficiency and compliance.

Scope of SOPs vs. Work Instructions

SOPs cover a wide range of processes, while Work Instructions focus on specific tasks. SOPs are high-level, providing overarching guidelines, whereas Work Instructions detail exact steps for individual tasks.

Scope of SOPs

Standard Operating Procedures (SOPs) encompass a broad range of processes and tasks within an organization. They provide high-level guidance, outlining the overall steps and expectations for achieving specific goals. SOPs are designed to ensure consistency, compliance, and efficiency across various departments or functions. Unlike Work Instructions, which focus on detailed, task-specific steps, SOPs cover a wider scope, addressing multiple tasks and processes. They serve as foundational documents, setting the framework for how activities should be conducted. SOPs are essential for maintaining uniformity and ensuring that organizational policies and regulatory requirements are met; Their broad scope makes them applicable to a wide audience, providing general guidelines that can be adapted to various situations.

Scope of Work Instructions

Work Instructions are highly detailed documents that focus on specific tasks or activities. They provide step-by-step guidance for completing individual operations, ensuring clarity and precision. Unlike SOPs, which cover broader processes, Work Instructions narrow down to the exact actions required for a single task. They are often used to support SOPs by breaking down complex procedures into manageable, easy-to-follow steps. Work Instructions are typically used by frontline employees who need clear, actionable guidance. Their scope is limited to the task at hand, making them invaluable for ensuring consistency and accuracy in execution. They are essential for repetitive tasks, where adherence to specific steps is critical for quality and compliance.

Level of Detail in SOPs vs. Work Instructions

SOPs provide general steps with less detail, while Work Instructions offer precise, task-specific guidance, ensuring clarity for each action required.

Level of Detail in SOPs

SOPs provide a broad overview of processes, outlining the essential steps and tasks required. They are less detailed, focusing on the overall framework rather than specific actions. SOPs are designed to be applicable across various situations, offering a general guide that can be adapted as needed. While they include key information, they avoid minute details, leaving room for interpretation based on specific circumstances. The goal of SOPs is to ensure consistency and compliance across an organization, providing a clear understanding of the process without overwhelming with intricate instructions. They serve as the foundation for more detailed documents, such as work instructions, which elaborate on specific tasks.

Level of Detail in Work Instructions

Work Instructions are highly detailed, providing step-by-step guidance for specific tasks within a process. They outline exactly how to perform each action, leaving little room for interpretation. Unlike SOPs, which offer a broader framework, Work Instructions focus on the practical execution of individual tasks. They often include precise methods, tools, and sequences to ensure tasks are completed accurately and consistently. The level of detail in Work Instructions is granular, addressing the “how” of each step, making them indispensable for ensuring compliance and operational efficiency. This specificity helps reduce errors and variability, particularly in complex or regulated environments where precise execution is critical.

Purpose and Focus of SOPs vs. Work Instructions

SOPs focus on overarching policies and compliance, while Work Instructions detail specific, step-by-step actions for task completion, ensuring clarity and precision in execution.

Purpose and Focus of SOPs

The primary purpose of SOPs is to establish clear, standardized procedures for repetitive tasks, ensuring compliance with organizational policies and regulatory requirements. They outline the “what” and “why” of processes, providing a framework for consistency across departments. SOPs serve as foundational documents that guide employees on the overall steps and responsibilities involved in completing tasks. By focusing on high-level objectives and compliance, SOPs help maintain operational efficiency, reduce errors, and ensure that all team members adhere to established protocols. They are essential for training new employees and maintaining quality control, acting as a reference point for understanding the broader scope of operations.

Purpose and Focus of Work Instructions

Work Instructions are detailed, step-by-step guides designed to assist employees in executing specific tasks accurately. Their primary focus is on the “how” of a process, providing precise actions, tools, and methods required to complete a task. Unlike SOPs, which cover broader processes, Work Instructions zoom in on individual tasks, ensuring clarity and consistency in execution. They are particularly useful for complex or critical procedures, reducing the likelihood of errors. By breaking down tasks into actionable steps, Work Instructions empower employees to perform their duties efficiently, even with limited prior knowledge. This level of detail ensures that tasks are completed uniformly, maintaining quality and compliance standards.

Structure of SOPs vs. Work Instructions

SOPs are structured with broad sections like purpose, scope, and responsibilities. Work Instructions are more detailed, often including step-by-step actions, visuals, and specific tools needed.

Structure of SOPs

SOPs are typically structured with clear sections like purpose, scope, responsibilities, and procedures. They often include approval signatures and revision histories. The content is organized to provide a broad overview of the process, ensuring clarity and compliance. SOPs may also contain references to related documents or policies. Each section is designed to guide users through the process systematically, making it easy to understand and follow. The structure ensures that all key aspects of the process are covered, from the initial steps to the final output, while maintaining a level of detail that is appropriate for the intended audience.

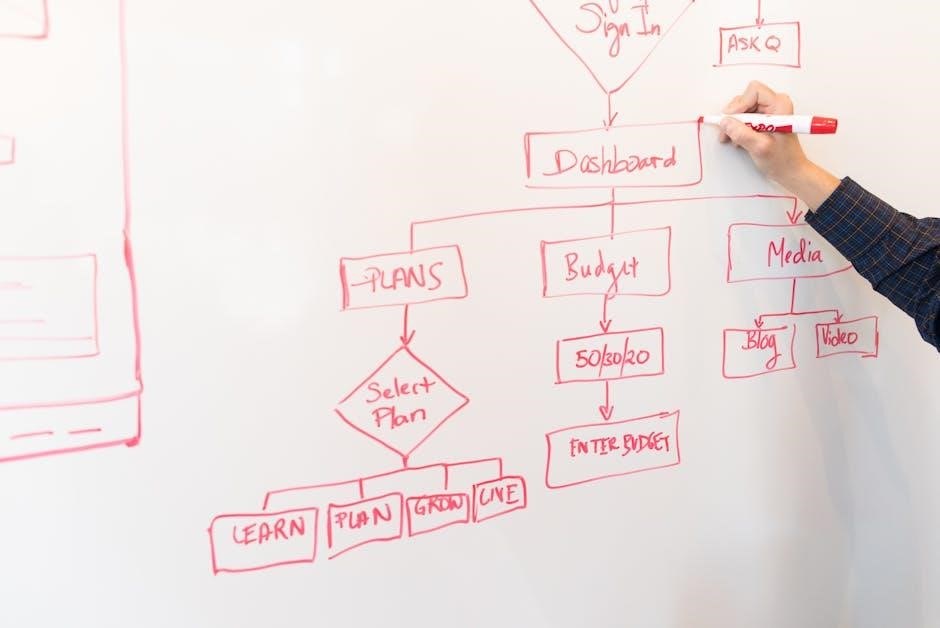

Structure of Work Instructions

Work Instructions are structured to provide clear, step-by-step guidance for specific tasks. They often include detailed descriptions of each action, required tools, and expected outcomes. Visual aids like diagrams or checklists may be added for clarity. The structure focuses on simplicity and precision, ensuring that users can follow the instructions without ambiguity. Each step is typically numbered or bulleted, and the language is direct. Unlike SOPs, Work Instructions avoid broader concepts, focusing solely on the task at hand. They may also include safety notes or quality checks to ensure compliance and accuracy. This detailed structure makes them indispensable for repetitive or complex tasks, guaranteeing consistency in execution.

Compliance and Regulatory Considerations

SOPs ensure compliance with regulations and policies, while Work Instructions provide detailed steps for adherence. Both support audits and maintain operational consistency across processes.

Compliance in SOPs

Compliance in SOPs ensures adherence to regulatory requirements and internal policies. SOPs outline the necessary steps to meet legal and quality standards, promoting uniformity and consistency across processes. They serve as a framework for ensuring that all activities align with industry regulations and organizational goals. While SOPs provide the overarching guidelines, they rely on Work Instructions for detailed execution. Non-compliance with SOPs can lead to legal issues, operational inefficiencies, and compromised quality. Therefore, adherence to SOPs is critical for maintaining accountability and ensuring that processes are conducted safely and effectively. In regulated industries, SOPs are essential for audits and demonstrating compliance with external standards.

Compliance in Work Instructions

Compliance in Work Instructions ensures that specific tasks are executed in accordance with regulatory standards and organizational policies. These detailed guides outline exact steps, tools, and methods required to complete tasks correctly. By providing clear, actionable instructions, Work Instructions help minimize errors and ensure consistency. They often reference SOPs but focus on the practical execution of tasks. Compliance in Work Instructions is critical for maintaining quality, safety, and legal adherence. They also serve as training tools, ensuring that employees understand expectations and can perform tasks accurately. Regular updates to Work Instructions are essential to reflect changes in regulations or processes, ensuring ongoing compliance and operational integrity.